Method

Tools

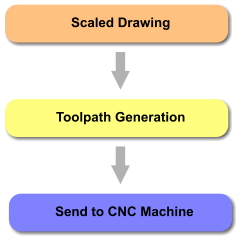

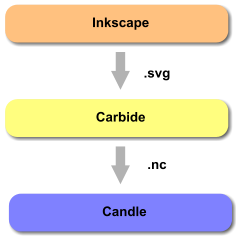

Toolchain Steps

Generate Scaled Drawing – Inkscape

Link to INKSCAPE

Scaled drawings are required to set the path of the cutting tool. These drawings are vector drawings where the lines have distinct start points and end points defined by coordinates.

Inkscape can also define line thickness, line colour and fill colour but this information is not required by the next toolchain step (Carbide). The file type I use for Toolpath Generation is .svg (Scaled Vector Graphic).

You can also download vector graphics from the internet to use with your CNC machine. Link to a few websites where I’ve found some good drawings:

![]()

Toolpath Generation – Carbide

Link to CARBIDE

So, the vector drawing defines the shape you want to cut. It does not define the size of the cutter, feed rate, depth of cut or dimensions of the material you are machining.

Carbide allows all these parameters to be factored in. Each line can be selected individually and the toolpath defined in stages or all at once depending upon what you’re trying to do.

Carbide generates the G-Code required to tell your CNC machine how to move and cut. .nc files are then loaded into the next toolchain step (Candle).

![]()

Send to CNC Machine – Candle

Link to CANDLE

My 3018 Pro came with an offline controller where the .nc file generated in the previous toolchain step could be put onto a memory card. This allows the CNC machine to be used without connection to a computer. I’ve never used the offline controller so no further details provided.

My preferred method of driving the CNC machine is to stream the data from a pc/laptop. Out of the box the 3018 Pro G-Code can be streamed over USB. After updating to bluetooth this is now done wirelessly.

Candle supports either USB or Bluetooth methods although I do need to close and reopen Candle if the pc hibernates or connection is lost with bluetooth.